Elite Coatings

Most Sought-After Concrete Coatings Company In Houston, TX

Strength And Durability In Every Application

Send us a message

I agree to privacy-policy & terms-conditions provided by the company. By providing my phone number, I agree to receive text messages from the business.

Experience the Elite Coatings Difference

Elite Concrete Coatings brings unparalleled expertise to every surface. Whether you’re aiming to beautify your home, enhance your outdoor areas, or upgrade your commercial space, our dedicated team specializes in Floor Coatings to deliver stunning, durable results. Trust Elite Concrete Coatings to provide the perfect solution tailored to your needs and experience exceptional service from start to finish.

Elite Coatings of Houston, TX

The Name You Can Trust On Any Floors!

FEATURES & BENEFITS

EXTREME DURABILITY

CUSTOM APPEARANCE

ENHANCED SAFETY

FAST INSTALLATION

CUSTOM APPEARANCE

What Makes Elite Coatings Better!

Epoxy Refinishing Options.

At Elite Concrete Coatings, we understand that your home, our personal space means a lot to you, and you spend a good majority of your time in your kitchen or bathroom. Your space not only has to look good but leave you with a feeling of comfort and welcoming.

Metallic Epoxy Floors

Metallic epoxy floors are the pinnacle of modern flooring solutions, providing an eye-catching, seamless surface that elevates any room in your home or commercial space.

Polished Floors

Ready to transform your commercial space with polished concrete flooring? Contact Elite Coatings in Houston, TX, for a consultation and discover how we can provide a durable, stylish, and slip-resistant solution tailored to your needs.

Elite Coatings Services

COMMERCIAL SPACE RESURFACING

Upgrade your commercial floors with high-performance metallic epoxy, flake, or quartz coatings. Ideal for businesses such as showrooms, salons, and auto shops, these coatings enhance both aesthetics and durability. Resistant to heavy foot traffic, chemicals, and wear, our coatings provide a professional, polished look that lasts. Available in a variety of styles, these floors are perfect for creating an inviting, safe environment in any commercial space.

METALLIC EPOXY - HOME INTERIOR

Elevate your home’s interior with the sleek and modern appeal of metallic epoxy floors. These stunning floors create a luxurious ambiance while offering long-lasting durability and easy maintenance. Ideal for living rooms, basements, or any interior space, metallic epoxy transforms your home with its rich colors and eye-catching finish. Experience a beautiful blend of style and strength that’s perfect for daily living.

GARAGE POLYASPARTIC COATNIGS

Transform your garage into a clean, functional, and attractive space with our durable epoxy or flake coatings. Resistant to stains, cracks, and impact, these coatings are designed to withstand the rigors of everyday use. Whether you use your garage for parking, a workshop, or extra storage, our floor coatings will keep it looking pristine while offering a slip-resistant, easy-to-clean surface.

OUTDOOR SURFACES

Revitalize your outdoor area with professional resurfacing that enhances both appearance and safety. Our pool resurfacing solutions include durable, slip-resistant coatings designed to withstand outdoor conditions while providing a fresh, clean look. Whether your pool needs minor touch-ups or a complete overhaul, our expert team ensures your pool is not only beautiful but also built to last for years to come.

EPOXY COUNTERTOPS

Transform your space with durable and stylish epoxy countertops and shower surfaces. Our expert team uses high-quality, water-resistant epoxy to create seamless, long-lasting finishes that not only look stunning but also provide exceptional protection against moisture, stains, and everyday wear. Perfect for bathrooms, kitchens, and more, epoxy offers a sleek, modern look that enhances the value and appeal of your property.

SALONS & BARBERSHOPS

Create a polished, welcoming atmosphere in your salon or barbershop with our custom flooring solutions. Our metallic, flake, or quartz coatings offer a stylish, durable, and easy-to-clean surface that is perfect for high-traffic environments. Designed for both function and aesthetics, these floors help set the tone for an upscale, professional space that impresses both clients and staff alike.

What's trending in Houston, TX?

In the dynamic world of interior design, metallic epoxy floors and countertops are setting the trend, and we at Elite Coatings are at the forefront of this innovative movement. We're not just following the trends; we're leading them, offering you cutting-edge solutions that redefine the standards of style and durability.

Our commitment to excellence ensures that we stay ahead of the curve, presenting these avant-garde options front and center for you to explore and embrace. Dive into the future of design with us, where the latest trends in epoxy finishes transform your space into a showcase of contemporary elegance and resilience.

Custom Flake Floors

Metallic Floors

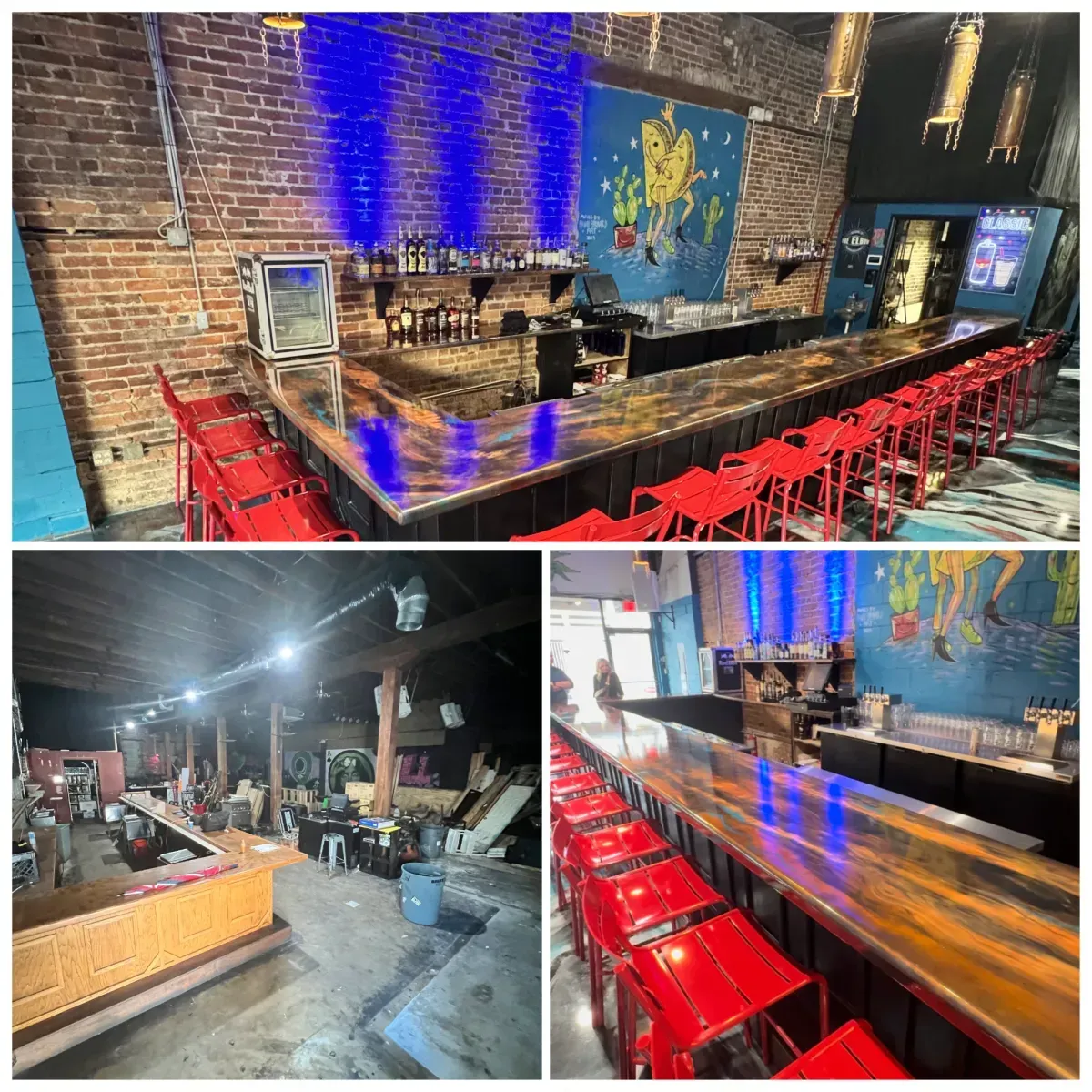

Epoxy Bar & Countertops

Our Happy Customers

The guys at Elite Concrete Coatings did an AMAZING job. I’m very picky and they matched and even exceeded my expectations. Tre showed up at my house, took some measurements, showed me some samples and explain the entire process. He was extremely knowledgeable, patient and not pushy at all. When I decided to get my garage done, they scheduled me very quickly and Tre and Justin did a great job. My floors are absolutely PERFECT! They fixed all the cracks and paid attention to every details. i would definitely recommend them to anybody who wants something BETTER than epoxy and that will last a very very long time. Really really happy with the results !! Thanks guys

Mickael Zibi

Texas City

Texas City

I’m very pleased with my garage floor. He did a fabulous job and it looks beautiful. He also clearly knows what he’s doing because it also contains enough grip so that in the winter my car does not slide.

Kathryn Mullen

Manvel

I’m very pleased with my garage floor. He did a fabulous job and it looks beautiful. He also clearly knows what he’s doing because it also contains enough grip so that in the winter my car does not slide.

Kathryn Mullen

Manvel

Ready to Transform Your Space?

As West Houston’s premier dealer, we offer top-quality epoxy concrete coatings for garages, patios, pool decks, and commercial spaces. Our quick-installation solutions enhance both aesthetics and durability, ensuring your surfaces stand out. Trust Elite Coatings for outstanding service and results.

Whether you’re looking to transform a garage floor, pool surface, or add a professional touch to salons and barbershops, our skilled team is committed to delivering high-end results with a focus on long-lasting quality and stunning finishes. Let us help you bring new life to your home or business with our exceptional craftsmanship and attention to detail.

High-quality, long-lasting paint finishes

Timely and hassle-free project completion

Experienced and professional team

Attention to detail in every coating layer

Use of eco-friendly & non-toxic materials

Excellent pre- and post-service support

Excellent pre- and post-service support

Transparent pricing with no hidden charges

Customizable color and texture options

Clean and safe work practices

Trusted by hundreds of happy homeowners & businesses

Google Reviews

Hear From Our Satisfied Clients

Send us a message

I agree to privacy-policy & terms-conditions provided by the company. By providing my phone number, I agree to receive text messages from the business.

Elite Concrete Coatings brings unparalleled expertise to every surface. Whether you’re aiming to beautify your home, enhance your outdoor areas, or upgrade your commercial space, our dedicated team specializes in Floor Coatings to deliver stunning, durable results. Trust Elite Concrete Coatings to provide the perfect solution tailored to your needs and experience exceptional service from start to finish.

Elite Concrete Coatings brings unparalleled expertise to every surface. Whether you’re aiming to beautify your home, enhance your outdoor areas, or upgrade your commercial space, our dedicated team specializes in Floor Coatings to deliver stunning, durable results. Trust Elite Concrete Coatings to provide the perfect solution tailored to your needs and experience exceptional service from start to finish.

Services

Metallic Epoxy Floors

Epoxy Finishes

Flake Floors

Service Areas

Friendswood

Pearland

League City

Galveston

Kemah

Clear Lake

Texas City

Seabrook

Service Areas

Service Areas

Santa Fe

Manvel

River Oaks

Copyright © 2024 Elite Coating

Copyright © 2024 Elite Coating